I found that it works best displaying lines and arcs and will run through the whole program quite fast. I played around with a few different G Code programs to see if I could find any issues.

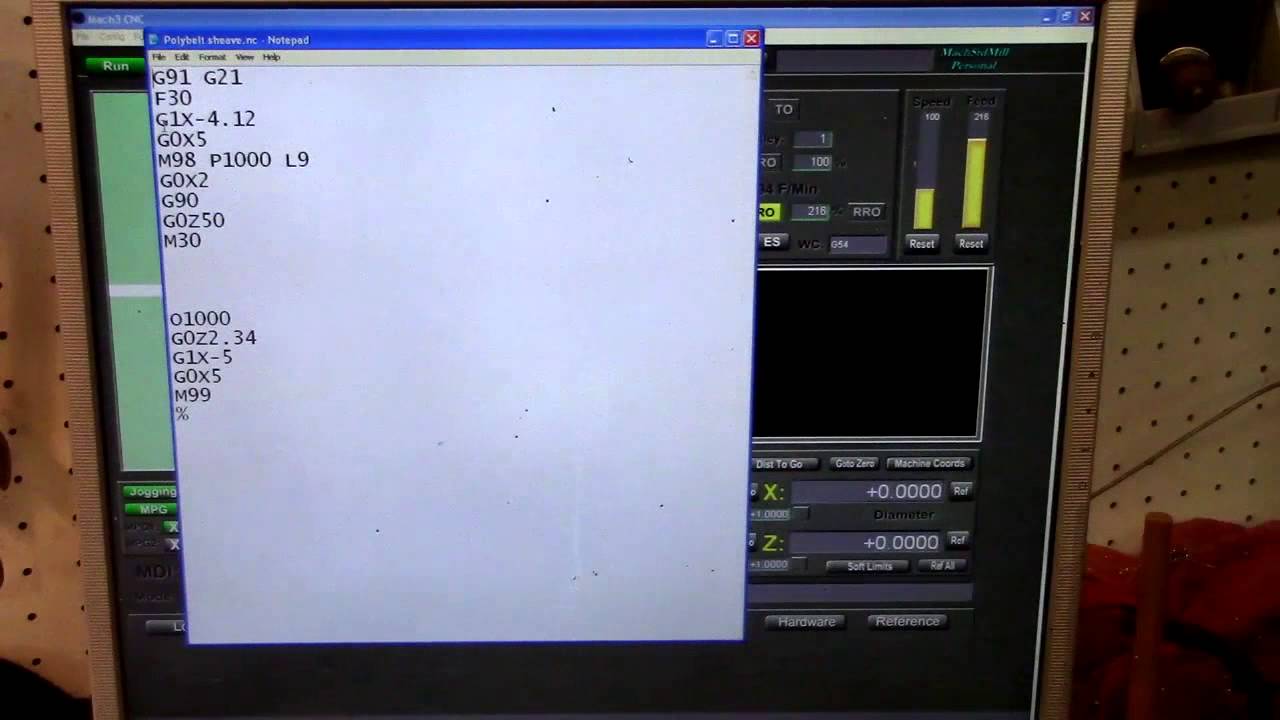

Just click on the different areas of the ball for different view perspectives or click the home symbol for a standard isometric view. Unless you have a couch in a warm workshop.Īnother way to orientate your toolpath backplot is by using the ‘view ball’ in the top right hand corner of the screen. Testing a small G code program in NC ViewerĪlso, being able to write and prove out a program while sitting on a living room couch is much more convenient than sitting in your cold workshop. This is why a standalone CNC G code viewer is really helpful when writing your own code. But you cannot use them to ‘type and test’ your own programs because they use a built-in G Code generator that processes the G code for you from the cad files. So no more typing out your programs in Wordpad hoping that it will be error free, you can program and prove it out as you go.Īll CadCam software products are equipped with a tool path simulator, it is what makes them so versatile. This is where a cnc simulator excels, most of them are also G code editors, allowing you to check your programs as you write them. Mistakes are easy to miss, especially when staring at a text file crammed full of numbers and prefixes.

Practicing writing your own G code can be tricky, even when you have been doing it for years. GCode Simulators are also known as a G code viewer, G code visualizer or a G code analyzer, help to prevent crashes and tool breakage which will save you money and frustration.

This type of software will give you a visual check of what your program will do before you run it on your cnc machine. The best way of doing this is by using a GCode simulator. Checking your GCode programs is critical to ensuring that your machine runs reliably and as trouble free as possible.

0 kommentar(er)

0 kommentar(er)